To meet the energy needs of the future, solar panels must be made more efficient and more responsibly.

Solar power has immense potential as a renewable energy source, helping humankind transition away from the production of fossil fuels, which are responsible for the vast majority of the greenhouse gases that trap the sun’s heat and destabilize the climate. In the last 15 years, public investment and private investment has grown solar from a negligible contributor to generating about 4% of global electricity production, and the International Renewable Energy Agency suggests that solar could account for 30-50% of electricity needs in the coming years. Recent growth in the field has been exponential — in 2022, according to the U.S. Energy Information Administration, the state of California generated 27% of its electricity from solar.

This anticipated proliferation underscores the importance of maximizing solar technology’s potential through efficiency improvements and sustainable design. Jason Baxter, PhD, professor of chemical and biological engineering at Drexel University, has embraced this opportunity with a holistic approach. His research focuses not only on enhancing solar cell efficiency but also on ensuring solar panels are made from sustainable materials, extending their usable lifespan and minimizing environmental impact.

“Over the last several years, one-third of new electricity generation capacity in the United States has come from solar,” Baxter says. “As coal-fired power plants are retired, solar and wind energy are becoming major players. The rapid growth of solar energy presents both an opportunity and a challenge, making research and innovation critical to maximizing its potential.”

One aspect of Baxter’s research focuses on making solar cells more efficient. He and his team are investigating the behavior of electrons within cadmium telluride (CdTe), the second-most commonly used light-absorbing material in solar panels after silicon. By utilizing specialized ultrafast pulsed laser spectroscopy methods, they aim to understand the limiting mechanisms that cause the recombination of excited electrons. This knowledge can then be used to guide changes in the processing and material properties to extend the duration of electron excitation, resulting in improved solar cell performance and enhanced energy conversion efficiency.

“There are several factors that we’re exploring,” Baxter explained. “We are working to understand the effects of different doping and alloying methods, where you change out some of the atoms within the CdTe to tune the electrical or optical properties. The community has known for a while that you can increase the spectrum of light absorption by substituting some selenium for tellurium, but now we are also investigating the possibility to increase the voltage by substituting antimony at parts-per-million levels. Even small changes to material composition or processing conditions can have significant effects on solar cell performance, so it is important to develop detailed understanding of the system.”

The research has attracted support and collaboration from government and industry partners. Baxter’s collaborators include researchers at the University of Delaware, the University of Florida, the National Renewable Energy Lab (NREL) in Colorado, and First Solar, a leading manufacturer of solar panels. Recent graduates from Baxter’s lab have landed jobs at NREL and First Solar.

In addition to efficiency, Baxter places great importance on sustainability throughout the lifecycle of solar cells. The choice of materials used in solar panels plays a significant role in their environmental impact. While silicon is the predominant material currently used as commercial solar absorbers, followed by cadmium telluride, alternative materials called perovskites have gained attention in research labs and are also on the verge of commercialization. Perovskite solar cells offer comparable efficiency to silicon, but they present challenges in their production.

“In lab settings, people have found that you can do a process called spin coating, where you drop an ink that contains perovskite precursors onto your substrate as it’s spinning really fast, and you wind up with a very thin layer that can be used in solar cells that are just as efficient as cadmium telluride and silicon,” Baxter said. “But most of the ink flies off the sides, so it’s a really wasteful and slow process, and you only wind up with really small cells.”

Together with departmental colleagues – professor Richard Cairncross, PhD, and associate professors Nicolas Alvarez, PhD, and Aaron Fafarman, PhD – Baxter is developing a roll-to-roll manufacturing process that they hope will yield more material with less waste. “We are trying to understand how we can control the crystallization of the perovskite film using a slot-die coater, which continuously feeds the ink onto the substrate as it passes underneath,”

Baxter elaborated. “By adjusting the pumping rate and the speed of the moving substrate, you can control the thickness of the film. There are a lot of really interesting aspects of fluid mechanics and heat and mass transfer at play that control the coating physics, along with material science in characterizing the resulting films and correlating their properties to the processing conditions.”

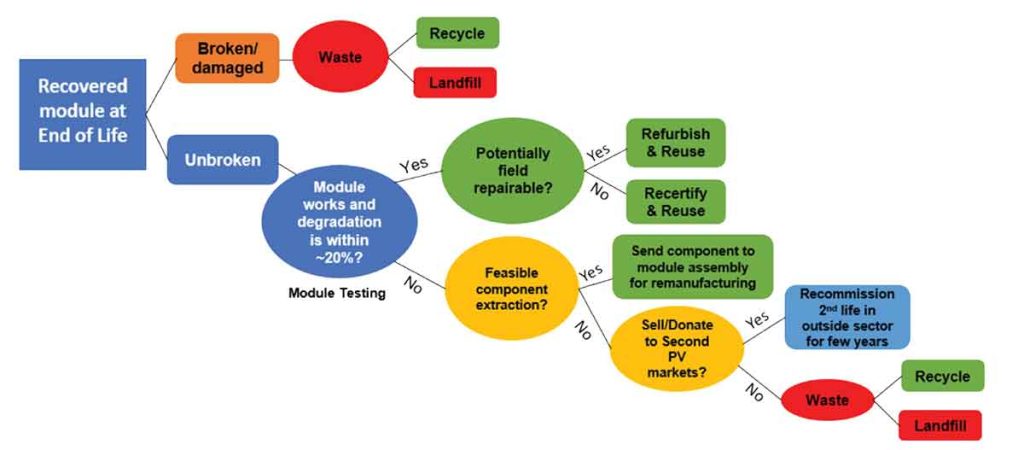

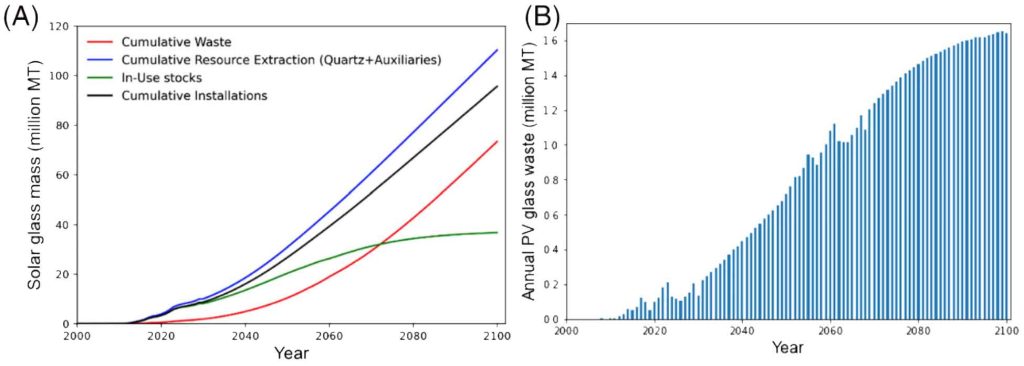

No matter the material used to create solar cells, an emerging concern is the waste created when the solar panels are retired. So, in addition to working on efficient technology and generating more electricity using less space, Baxter’s research explores sustainability on both ends of the materials’ lifecycle.

“If we scale solar at the level that we hope, you also have to consider that there’s a 35–to 40–year lifespan for solar panels, and then you will have a waste curve that’s similar to the adoption curve, but with a delay of a few decades,” he explained. “We’re using dynamic material flow analysis to understand how improving efficiency or durability can reduce the impact of all this production. You also want to be sure that you’re asking questions about the safety and environmental impact of the materials being used.”

Baxter’s commitment to sustainability extends beyond solar cells to other renewable energy technologies. Collaborating with departmental colleagues, assistant professors Megan Creighton, PhD and Amir Farnam, PhD and associate professor, Grace Hsuan, PhD, Baxter and his team investigate the management of retired wind turbine blades and explore possibilities for recycling and repurposing composite materials. One possible pathway considers combining waste fiberglass reinforced polymer composites from wind turbine blades with waste coal combustion ash and waste glass to produce lightweight aggregate for construction and geotechnical applications. The team aims to create valuable manufacturing products while minimizing environmental impact. The work is supported by the College of Engineering’s Longsview Fellowship program, which encourages interdisciplinary research intersecting with the pillars of the college’s strategic plan.

As the renewable energy revolution progresses, Baxter’s lab serves as a center of hope, addressing the challenges of improving efficiency, extending lifecycle and minimizing environmental impact. Moreover, it serves as a training ground for future energy thought leaders.

“The most important product of my lab is the students we are sending out into the world, ready to join industry, work in national labs or expand on this research at other universities,” Baxter said. “Drexel is a great place for both graduate and undergraduate students to gain the skills and experience needed to support the rapid growth of the solar and wind industry and to develop a more circular, sustainable economy.”